Advantages and disadvantages of PLC - To add more considerations before creating a system control especially a PLC-based system control, we need to know the advantages and disadvantages of PLC in general. While different PLC manufacturer will have their own advantages and disadvantages. So after you choose to use PLC, make sure you know which PLC type and manufacturer you will choose.

|

| advantages and disadvantages of PLC |

Advantages of PLC

There are many of the PLC advantages as described below :

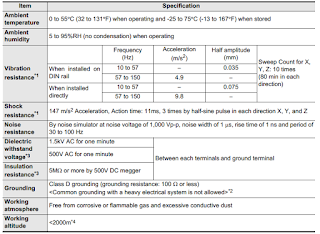

- It can withstand vibrations, temperature, humidity, and noise.

Basically, each plc that build by the manufacturer already fulfill specific safety standard. This standard test the hardware to withstand industrial environment and it show that the hardware is capable to handle that environment. A higher PLC specification and special treatment might require for special condition/environment. From machinery, manufacturing process, line automation, it's all show that PLC is reliable. |

| Technical specification which shows PLC ability to withstand vibration, temperature, etc |

- Simplified the need for multiple devices, ex: timer, counter, etc.

As prescribed in another article, PLC can simplify and reduce another component like timer and counter. It has some features that work as same as the components that commonly use in the industry. This also means less space is needed to build the system control. Another thing, PLC provides more possibilities to build the system control. By using PLC, more logic and function can be included in the system control.

- Easier to program

As plc getting more improvement, it is easier to program PLC, we can use laptop or PC to program and monitor the PLC. The programming language of the PLC is also considered easy to understand. Most of the PLC manufacturer feature ladder programming in their PLC. The ladder can visualize the logic that uses in the program, make it easier to program the PLC. It is also possible to simulate the program that we created so we can see whether the program is correct or not before we applied with the real system.

- Able to create Pulse or PWM

PLC have solid state switch which can provide unlimited switching cycles at a very fast speed. This makes it possible to be used for the actuator or device that required pulses. Various range of pulse can be created by using PLC, this depends on the specification of the PLC.

- Can be integrated with interface (ex: HMI, PC) and other PLC

One of the advantages of the PLC is it can be integrated with interface device like Human Machine Interface (HMI). The combination of these two devices is commonly used in the industry. HMI can monitor the output and give input to the PLC, while PLC processed all the input and output. PLC can also be integrated with another PLC to perform a more complex task. Other than that, PLC can be integrated with PC. |

| FX3U PLC battery (mrostop.com) |

- Easy to maintenance

PLC is built such of it from the manufacturer, so that it can be maintenance easily. All that needed is to clean the PLC, especially if its placed in a dusty environment. We also need to look out for the battery of the PLC. This battery is important to keep latched data or memory and usually will wear out after a few years.Other than that, the environment will play a big role in the PLC life time.

See : When and Why using PLC?

Disadvantages of PLC

Now let's move to the disadvantages of PLC. There are few disadvantages of PLC as described below :

- Cost

Actually, the cost is relative. As if the system control become more complex, the PLC specification will be higher and better, this required more cost. Just compared the cost that needed to buy the PLC and other components that support it with the function of the system control.

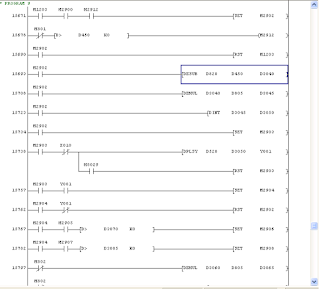

- If the system is too complex, troubleshooting won't be easy

If the system is getting too complex, then it means the PLC program will be longer. And if the system doesn't work as it should be, then the troubleshooting will take time and it won't be easy. The programmer will work harder and required more skill. This will also provide loss, as the system control need to stop to find out the problem and solve it.

|

| Ladder PLC program |

- Working temperature

PLC is fit for the common environment, but if its need to work in a harsh environment which is very hot or very cold, then it requires special treatment. Each PLC has limitation related to its ability to work in specific temperature. You might need to read the manufacturer manual or ask the manufacturer what special treatment should be applied, if the environment is beyond the PLC capability.

So, it's all the major advantages and disadvantages of PLC. While each manufacturer and different PLC type have their own advantages and disadvantages. Put more consideration before choosing which PLC type and manufacturer that will be used.

Feel free to like, share, comment. Thanks for reading.

Feel free to comment according to the article above.

EmoticonEmoticon